Overview

Garmin's Sonar Engineering Team creates several dive watches and air tank sensors designed to communicate with each other using their SubWave Sonar technology while underwater. Until recently, to test and calibrate these precise devices, Garmin attached them to a boat using 12 ft PVC poles, leading to several feet of deflection during testing and decreasing both accuracy and repeatability of results.

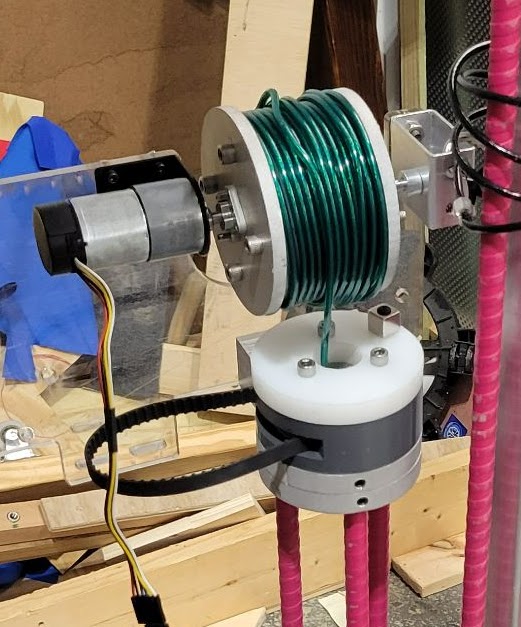

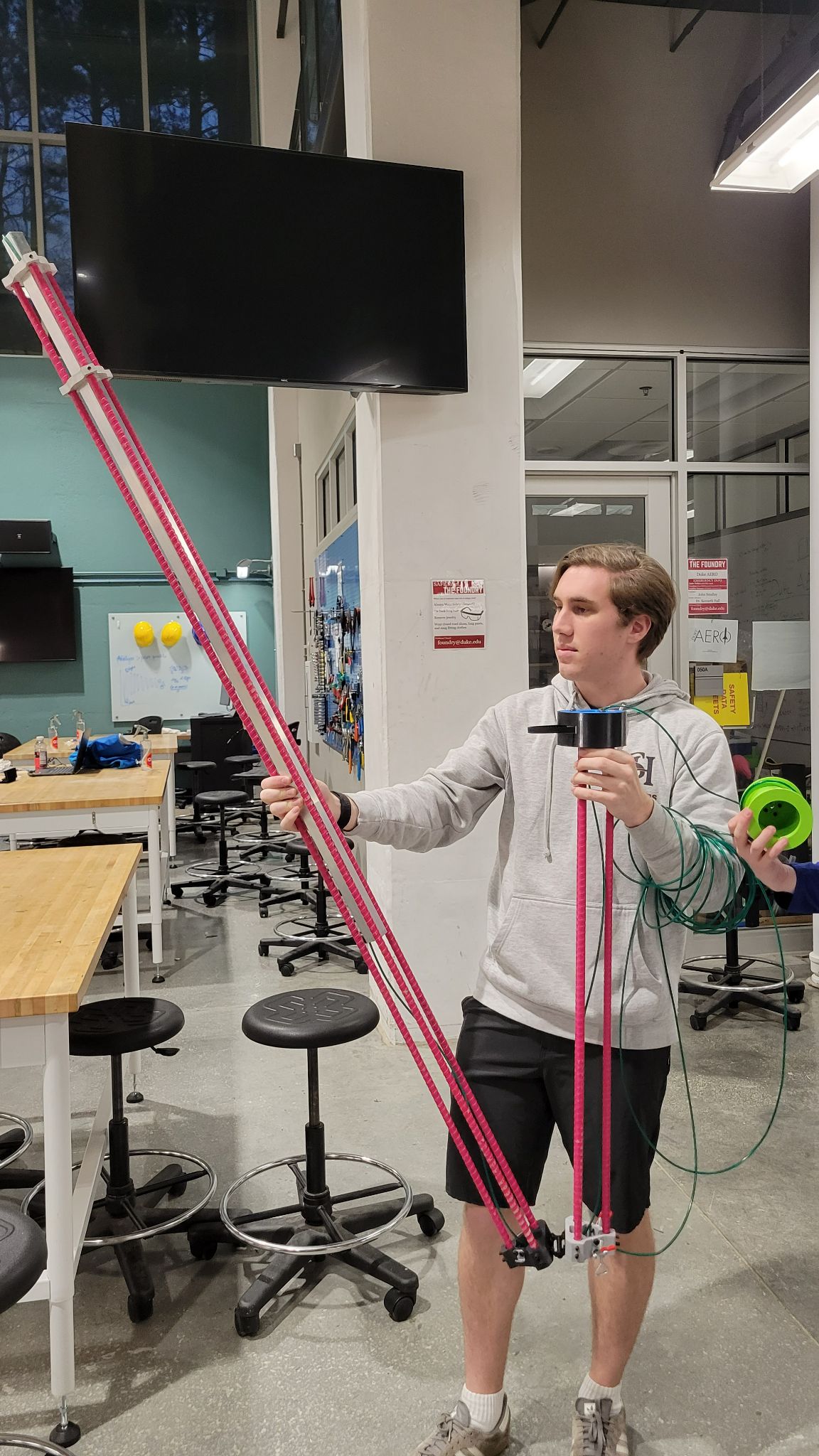

To make the testing and calibration process more stable, accurate, and consistent, I worked with a team of engineers in my EGR 102 class to design and build a new mounting system that would hold the dive watches and air tank sensors fixed in position underwater, while being controllable using a web app to set the exact depth and angular position of the devices being tested.

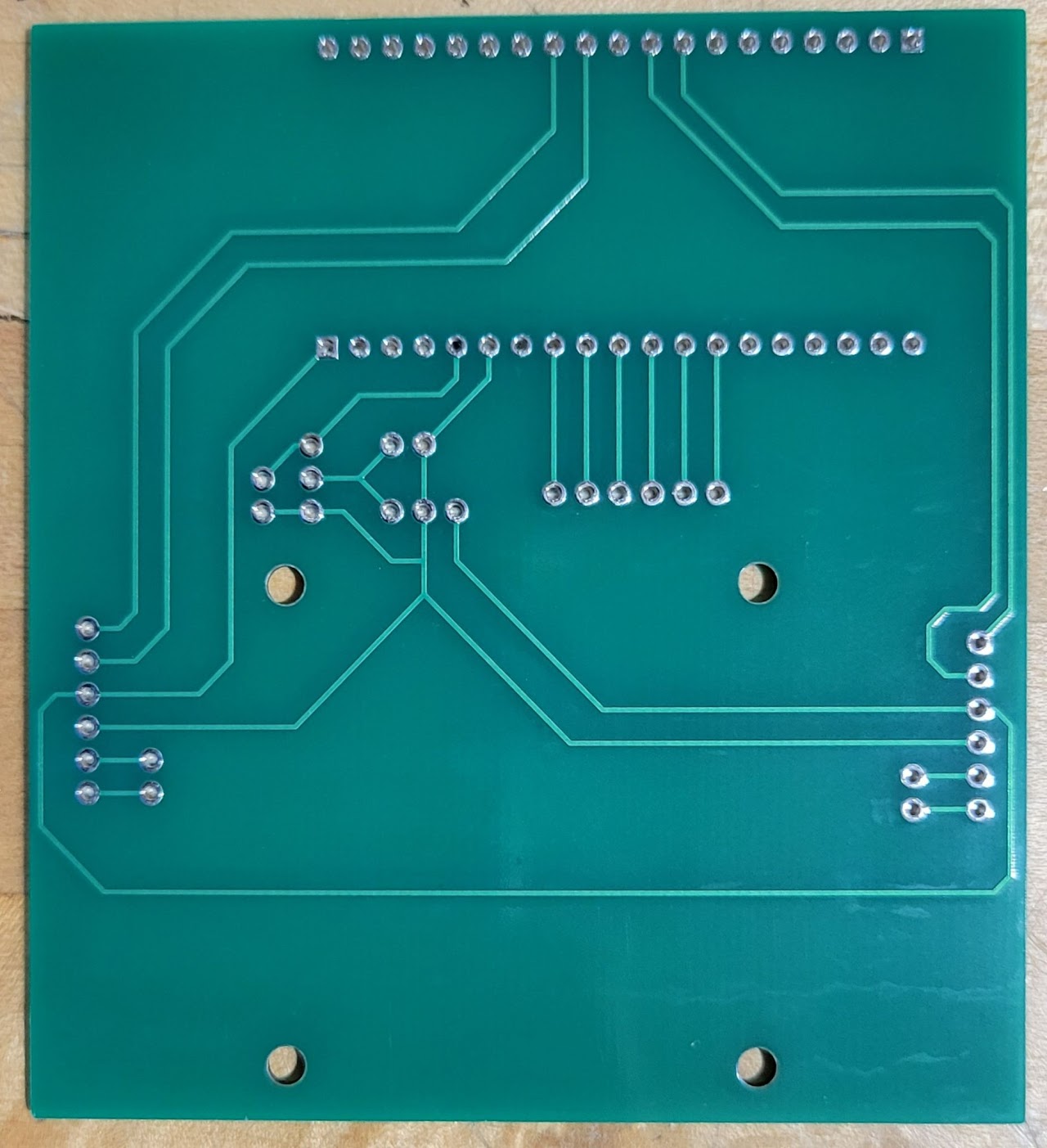

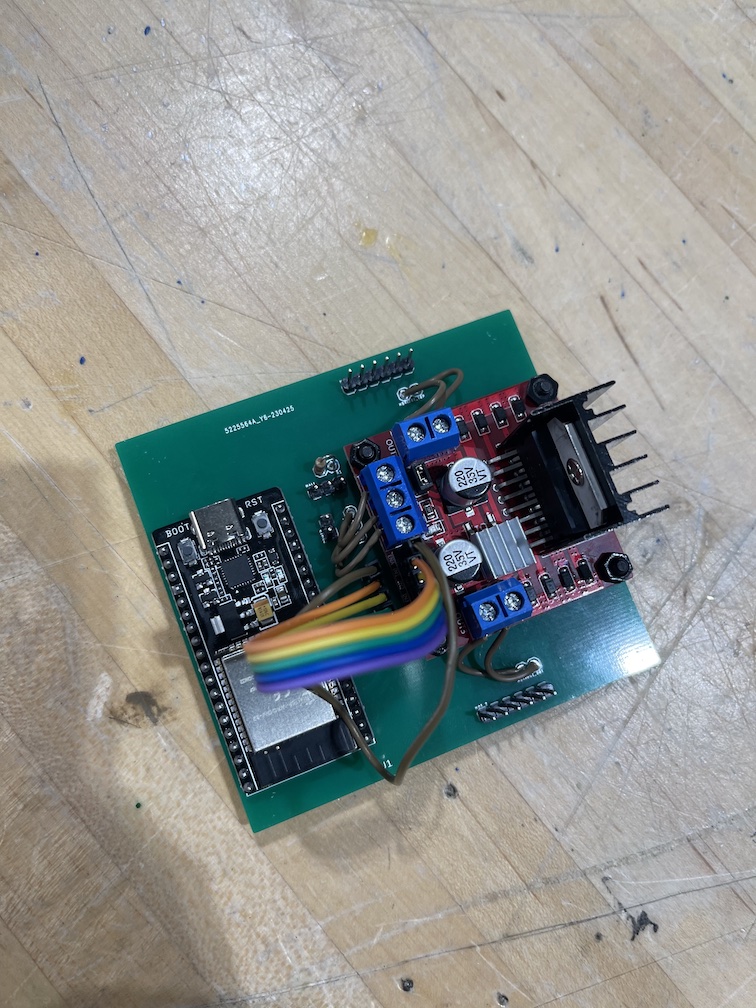

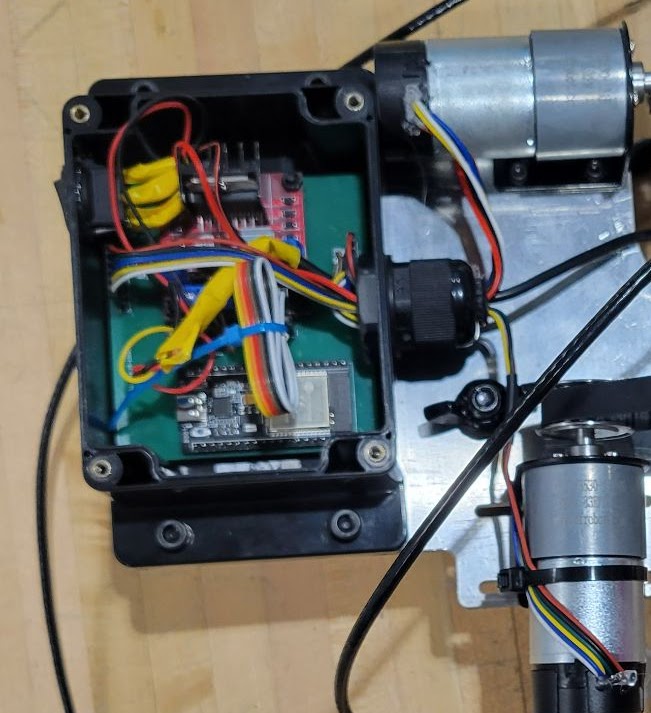

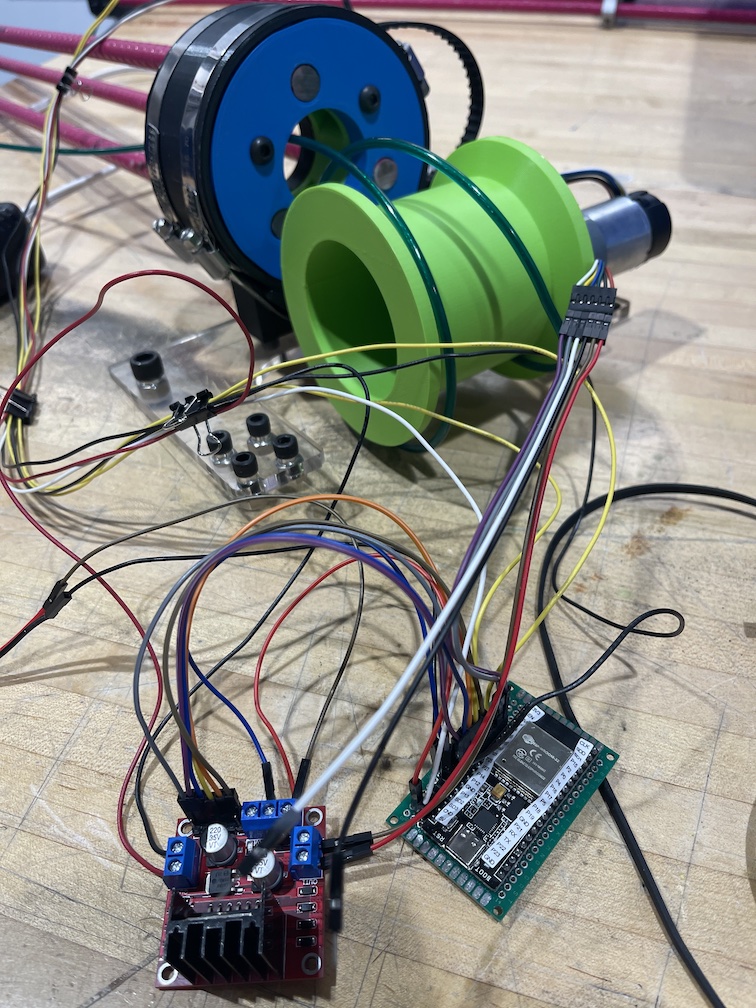

As electrical team lead, I personally designed the mechatronic control system, from the motors used to physically move the testing rig to the UX of the web app used by engineers while performing tests, as well as all the microcontrollers and firmware in between.

The new testing system installed on the boat.